Prototype To Production

At Parkway, we can step in at any point in the process. We can take a prototype and engineer a way to effectively manufacture the part and reduce costs or we can take an existing part, currently in production, and break down the process and figure out a more efficient way to make it. As people in manufacturing know, there often is a long bridge to travel from prototype to production. Bridging that gap is what we do.

Our customers are on very tight schedules. In some cases, if they miss testing dates it can cost them millions of dollars. They choose Parkway Products because our engineers are the best in the business. With our experience and innovation working with plastics, you can rest easy knowing that we will meet your needs, even if they are "impossible."

Engineering Solutions

Our engineers can work with yours to optimize the design and produce parts in weeks when other companies take months. People talk about lead times, but that doesn’t mean anything if something has to be ready in two weeks. We love challenges. We have configured Parkway’s manufacturing process to be dynamic and have the excess capacity to step into any emergency.

Impossible is what we do

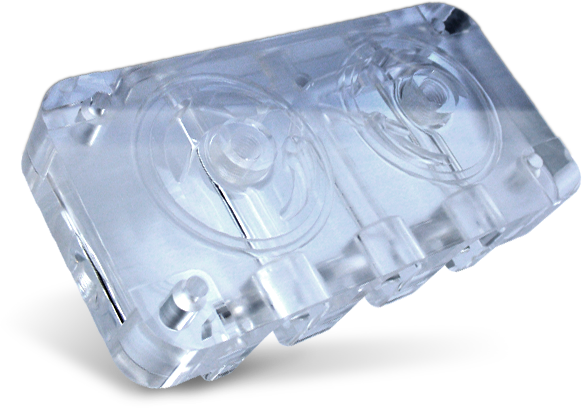

Parkway offers the fabrication and distribution of stock plastic shapes, machining of plastics, custom injection molding of engineered plastics. We produce complex, precision and high-tolerance plastic components for leading companies in many industries, including aerospace, defense, food service and agriculture.